How to Choose the Best Precision Screwdriver Set

If you work with delicate screws and other small fasteners, a precision screwdriver is a must. When it comes to working with small components and modern electronics, buying the best precision screwdriver set can be a huge expense, but it can be of great value in helping to ensure you get the job done right.

Consider when choosing the best precision screwdriver set

As with general-purpose screwdriver sets, there is a wide variety when shopping for the best precision screwdriver set. The following notes detail your options so that you can get a complete overview of the features and benefits each set can offer. Knowing these details makes it easier to choose the right tool, whether you're a hobbyist or a full-time professional.

Purpose

All screwdrivers serve two basic purposes: to insert or remove screws or fasteners. are suitable for many household tasks DIY screwdrivers, and precision screwdrivers often have to offer more.

The precision screw is very small and easy to falls off, and it is very difficult to find it. If it's lost in a delicate machine, this little screw can be difficult to retrieve and can even cause serious damage. Also, the screws may be too small for initial alignment in your fingers.

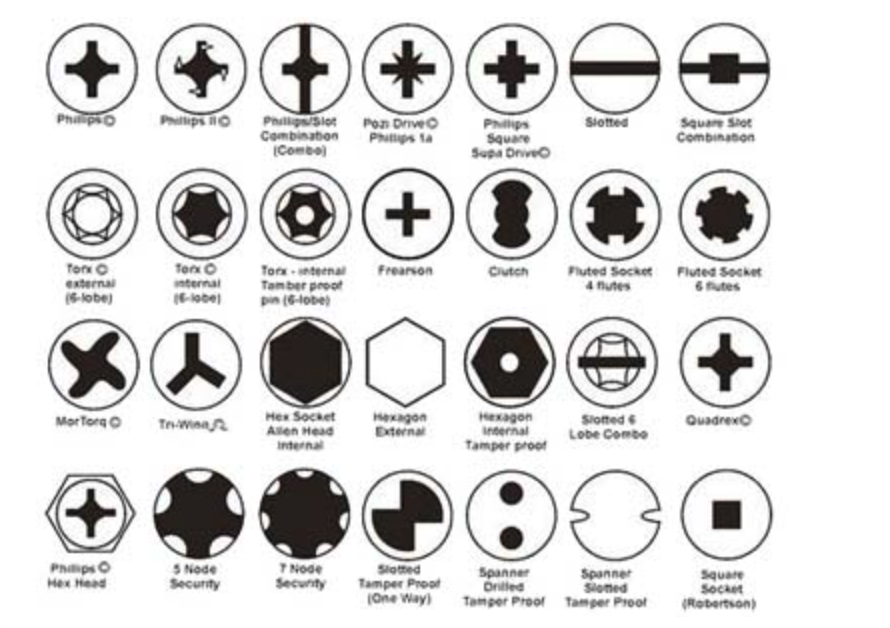

Various fasteners also need to be considered. A set of precision screwdrivers usually needs to be suitable for more types of fasteners than just ordinary grub or Phillips head screws. The following sections provide solutions to help address these challenges.

Screwdriver Types

Precision screwdrivers can be divided into two main types: one-piece manufacture with handle, shank, and blade, or manufacture with a single handle and various interchangeable bits. The latter is similar to the kind of tool you often find in a mechanic's or engineer's scrolling toolbox but on a much smaller scale.

Integral precision screwdrivers can be purchased as separate items, but they are usually supplied in sets of 4 to 12 tools, usually in boxes or tool rolls. They either have a molded plastic handle like a standard screwdriver, or they are all-steel construction and are commonly referred to as mini or jeweler's screwdrivers.

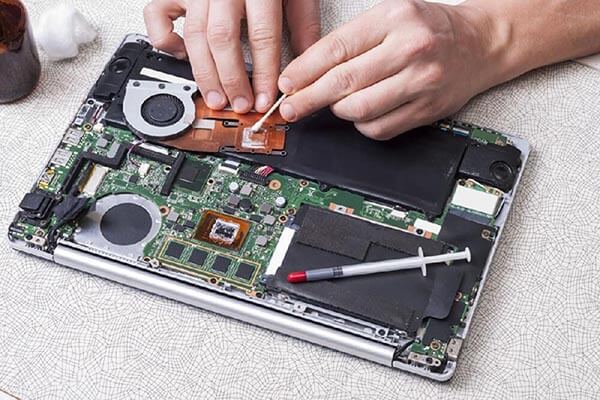

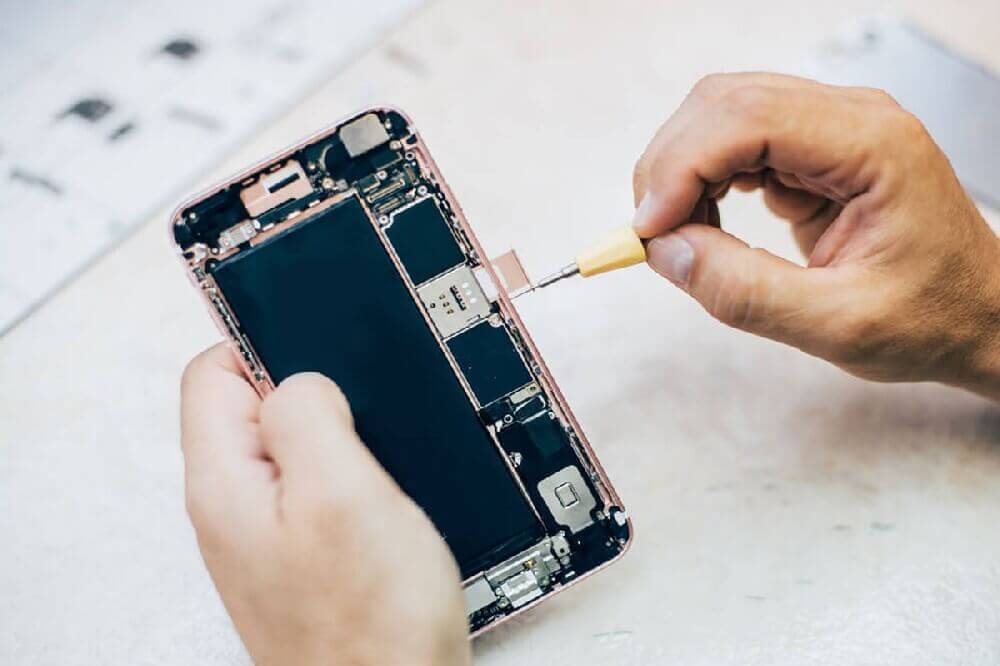

Interchangeable precision screwdriver sets often include more items than just screwdrivers. In some cases, more than 100 pieces are included. They can be general in nature or specialize in tasks like laptop or cell phone repair, gun building, or watchmaking.

Dimensions and Display

The Precision Screwdriver Set is smaller and lighter than standard screwdrivers. Tiny precision screwdrivers typically come in plastic cases that easily slip into jackets, tool belts, or work clothes pockets. While metal casings tend to be more durable than plastic casings, they also come in fitted tool rolls made of heavy-duty nylon. Budget precision screwdriver sets may not include a housing or reel and are supplied as loose tools. If you have a good toolbox to carry them around, that's fine.

The way the screwdriver is presented in the case varies. With a precision screwdriver with interchangeable bits, you'll usually find a hinged lid that opens to display the tool at an oblique angle, making it easy to select the tool you need. Size and fastener type can be clearly marked. All-in-one screwdrivers in the tool roll may have similar markings, but not always. While some have marked handles, it can be frustrating to have to check each tool before using it.

Materials

A precision screwdriver can be divided into three parts: handle, shank (shaft), and blade (replaceable bit).

On larger precision screwdrivers, the handle is usually plastic, usually hard-wearing cellulose acetate. Rubber inserts can be added to improve comfort and grip. On a miniature or jeweler's screwdriver, the handle is usually steel.

The handle is almost always a steel alloy, chrome molybdenum, or chrome vanadium. Both are widely used to make tools and combine great strength with a degree of flexibility. They are also highly rust-resistant. Chrome can be added to make them easier to wipe clean. Aluminum is occasionally used because it is light and does not rust. It's not as strong as a steel alloy, so it's limited to those precision screwdrivers that only need moderate torque to turn fasteners.

Wear on the blade or drill bit is the first to bear the brunt. On budget screwdrivers, they can be the same steel as the handle. Other materials used are high-speed steel (HSS), S2 steel, high carbon steel, titanium, and stainless steel, each adding hardness, and durability.

handle

the handle is especially important in a precision screwdriver set as it needs to provide control when working in challenging situations. A slight slip can be the difference between a successful repair or further damage.

The shape of the handles may allow the same full grip as a standard screwdriver, but they are usually shorter with swivel end caps. The end cap sits in the palm of your hand, while the narrow or tapered portion allows you to turn the tool with just your fingertips. Precision screwdrivers used in watchmaking are an example.

The handles on pocket precision screwdrivers are usually textured (knurled) steel for extra grip. They often contain useful clips. On some models, there is a hole through, allowing a rod to be inserted to provide extra torque when loosening stubborn fasteners.

An interesting handle design comes from a stubby precision screwdriver with interchangeable bits stored in the handle. It offers good versatility while remaining very compact.

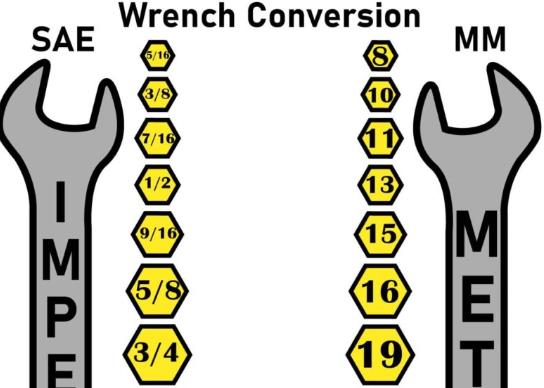

Shanks, Blades, and Bits

While the shank may seem like a basic piece, its length can have a considerable impact on your choice. Sometimes space constraints require a short model. Stubby precision screwdrivers exist both as stand-alone tools and as tools with interchangeable bits. At the other end of the scale, there are elongated shanks designed to reach fasteners buried deep inside the device. Most shanks are round, but some have facet or hexagonal cross-sections. This allows a wrench to be installed to provide additional torque if the fasteners are difficult to move.

Since there are more than a dozen different types of fasteners in common use, having the right blade or drill is critical. "Approaching" is not acceptable as any loss of engagement between the tool and the fastener will result in loss or damage. On high-quality precision screwdrivers, the insert and drill are machined to fit precisely.

For extra positioning help, many blades and bits are magnetized. This is also useful for picking up dropped screws. Magnetic fields are not strong enough to cause problems in delicate electronics. A blade with retractable jaws may help when screw holes are hard to reach. It provides a firm hold until the fastener is in place, at which point the jaws are released by pressing down on the screwdriver cap.

Additional Features

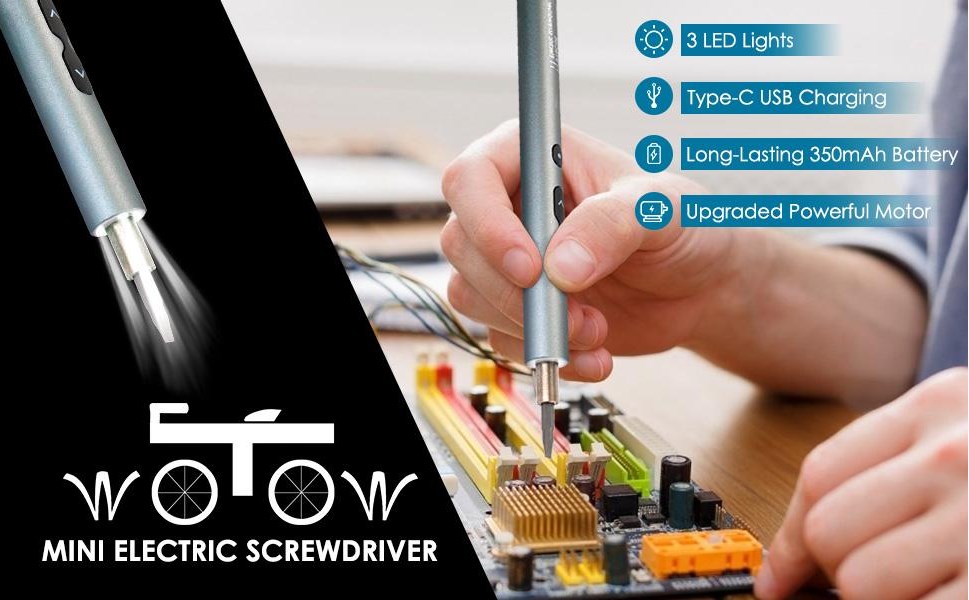

The best precision screwdriver set offers innovative solutions to a variety of problems commonly associated with repairing modern devices such as gaming consoles, smartphones, and tablets. Some precision screwdriver holders come with a small collet and are capable of accepting a flexible shaft. This allows access to screws that would otherwise be inaccessible. Others contain an extension so a single screwdriver can be used with shafts of different lengths.

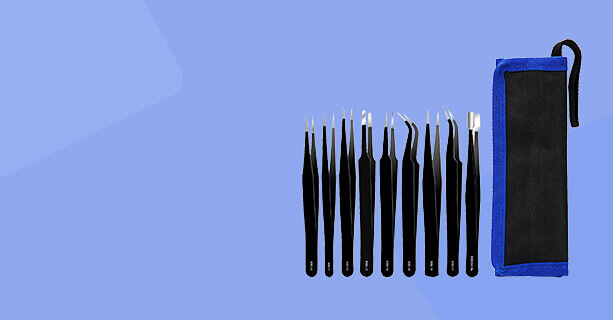

Access to some of these devices is not done by loosening the screws, but by using a plastic tool to open the case. Some of the precision screwdriver sets on our list include these and other useful items such as electrostatic discharge (ESD)-coated pliers, scissors, or tweezers to prevent damage to sensitive electronics.

Our Top Picks

Now that you know more about precision screwdriver sets, it's time to start shopping. Preferred products are selected based on the criteria listed above as well as the tasks presented in the category, the value provided, and the manufacturer's reputation for reliable, durable products. The following list includes some of the best precision screwdriver sets available.

Precision Screwdriver Set FAQ Answers

Now that you have a better understanding of the power and versatility that the best precision screwdriver sets can offer, you may have some additional questions. Below you'll find answers to some of the most popular questions.

Q. What is a precision screwdriver set?

The precision screwdriver set includes tools for handling small fasteners. They are usually smaller than standard screwdrivers, although they may be more elongated. The set usually consists of a single handle with multiple interchangeable bits.

Q. How to use a precision screwdriver?

Many precision screwdrivers are used just like regular screwdrivers. The smaller model has a cap at the end that sits in your palm, and its body rotates independently. It allows you to turn the screwdriver using only your thumb and middle finger.

Q. How to maintain the precision screwdriver?

It's always a good idea to buy a set in a case or tool roll to keep them from bumping into other tools and damaging them. Wipe them down quickly before putting them away, paying attention to the tips, which can pick up tiny particles that can cause wear or prevent proper engagement the next time you use them.

Q. How long is the service life of a precision screwdriver?

Complete screwdrivers with hardened tips last for years, while interchangeable precision screwdriver bits are even more versatile. Some are equally durable, but others should be considered consumables and should be replaced as soon as they wear out.

If you are looking for a professional screwdriver manufacturerto customize your precision screwdriver set, feel free to contact us today! We provide high-quality, customizable toolsfor various repair needs.

BECOME A WHOLESALE PARTNER

Get 10% off on orders over 500 units. We offer exclusive B2B pricing, OEM packaging, mixed batch support, and fast global delivery. Partner with a trusted screwdriver manufacturer to boost your margins.