15 Essential Tools for your Watch Repair Kit With operation method

Many of our friends who have just entered the watch repair industry may not be very familiar with the tools required for watch repair and the specific uses of these tools. Today, we will introduce some common tools used in watch repair, with instructions and usage methods. Hope to help everyone.

1. Eyepiece

Purpose: Due to the delicate parts of the watch, each component must be seen through a magnifying glass. Usually, you need to prepare magnifying glasses with different magnifications from 3 to 12 times. The low magnification is mostly used for disassembly and assembly of parts, and the high magnification is used to adjust the balance spring and check whether the pendulum shaft has skewed or extremely small parts.

Usage: You can directly open the upper and lower eyelids to clamp the magnifying glass, or you can use iron wire or buy ready-made iron wire loops, and put the magnifying glass tightly on your head. The length of the iron wire can be adjusted by yourself, and people with nearsightedness and glasses can also directly Put it on the mirror and use it.

2. Watchband support seat

Purpose: A support base used to fix the strap to facilitate disassembly when adjusting the length of the strap.

Usage: Place the thimble of the watchband vertically on the movable bolt of the movable watch section in the direction of the arrow, tap it with a mallet, and the movable bolt will detach. After adjusting to a proper length, you can install it on the other side in the same way.

3. Remove the bottom cover knife

Purpose: Open the back cover of the watch.

Usage: Hold the watch firmly to avoid slipping and cut the back bottom cover. Use the bottom cover knife to forcefully press in from the edge opening of the back bottom cover and pull it up. There is a shorter knife at the other end of the bottom cover knife, which can be used for belts. The belt of the watch is removed.

Note: Only applicable to the design of the press-type rear bottom cover, screw-in bottom cover, lock screw bottom cover or special bottom cover must use a dedicated meter opener.

4. Meter opener

Usage: There is a rotary knob for adjusting the size at the back. After adjusting the watch opener to the proper size of the watch, press and rotate it to the left to open the back cover. It is better to use it with the watch holder.

5. Watch holder

Purpose: There are different sizes of front and back for men's and women's watches. The wooden material is not easy to damage the case. With a watch opener, the back cover of the watch can be easily and safely opened.

Usage: Put the watch back up in the holder and adjust the side rotary knob to adjust the size, and then use the watch opener to open the back bottom cover.

6. Typhoon

Purpose: Remove dust on parts. Usage: Just hold and press several times.

Note: After the watch is assembled and oiled, avoid blowing air against the oil hole of the gem to prevent the oil in the oil hole from being blown away.

9. Take the child

Purpose: Clamping small parts such as arbor, wheel center or cylinder for easy fixation. It is cut into four parts from a cylinder. When clamping parts, the force will be averaged and the parts will not be damaged. There are 4 different specifications at both ends.

Usage: Insert the stem into the rotary lock, then the crown can be easily removed, and it can be used for various types of cylinders.

10. Watch repair plasticine

Application: Remove the dust or excess oil stains on the parts and the oil stains on the quartz watch rotor.

Usage:Cover the tip of the clip with some rubber paste dug out by the clip, and gently stick the dirty part.

11. Movement fixing seat

Application: Due to the different sizes of the movements of men's and women's watches, there are two sizes, which are used to fix the movements and facilitate disassembly.

Usage: Place the outer ring of the mechanism on the groove of the fixing seat smoothly and lock it gently. Don't use too much force to avoid damaging the plate.

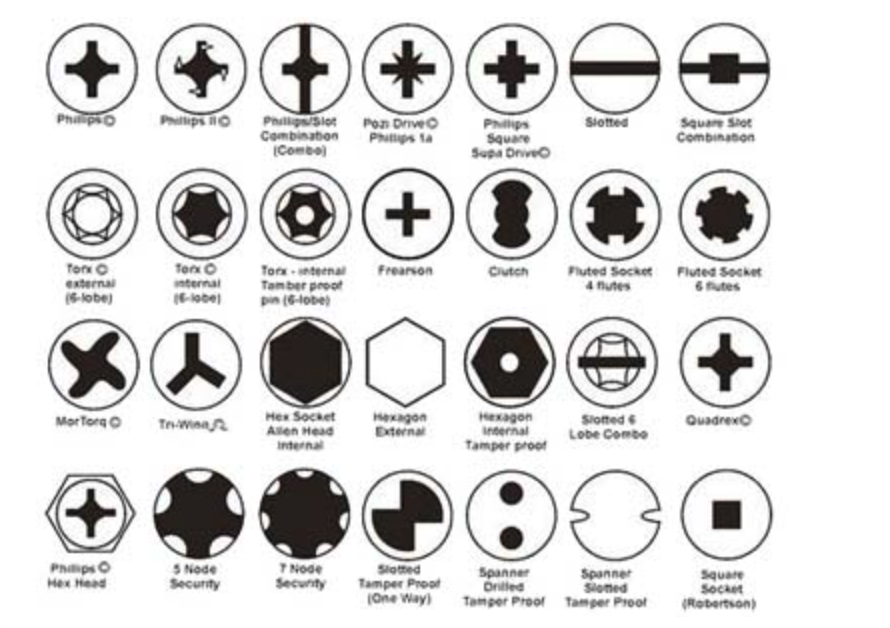

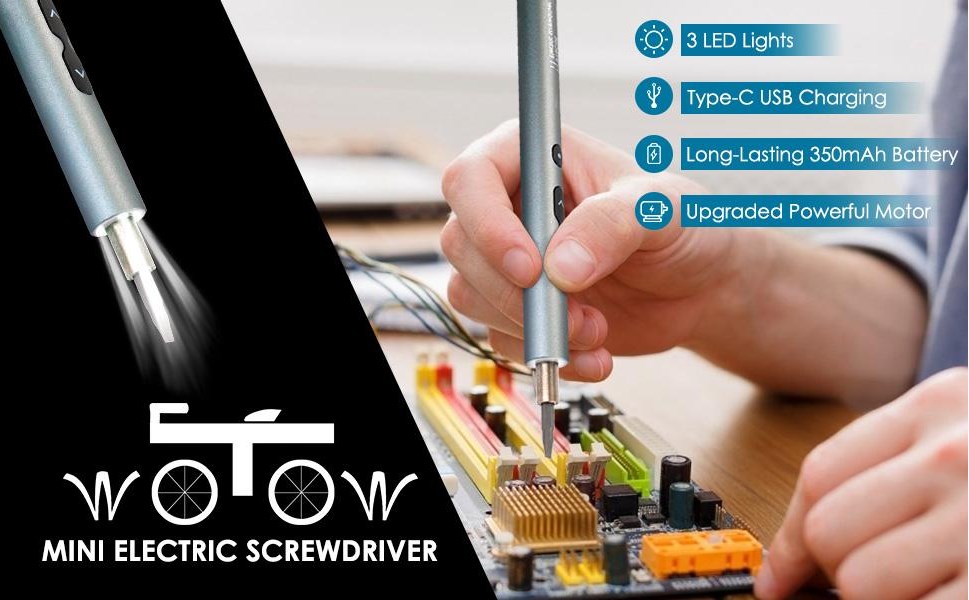

13. Screwdriver

Application:There are different combinations of 10 pieces, 9 pieces and bulk, and spare blades are attached. As long as the screw fixing hole on the screwdriver is loosened, the blades can be replaced.Each knife has a color to distinguish the specification, and the number of the outer ring of the cutter base represents the diameter of the knife.

Usage:When using, it must be perpendicular to the machine board, and the size of the screw should be compared first, and the appropriate size should be selected, so as not to damage the screw cap or scratch the machine board due to careless sliding.

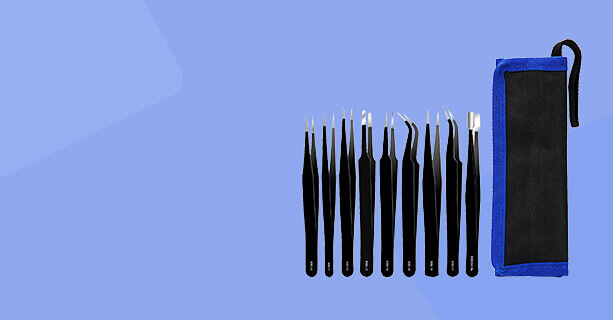

14. Diamagnetic tweezers and grindstone.

Application:To clamp the parts, in order to avoid the parts being magnetized, it is best to use the tweezers with anti magnetic function, which is usually enough to prepare 2-3 tweezers for use in the machine core.No. 3 tweezers or those with a thicker tip are usually used to clamp general parts such as machine core, splint, screw, gear, etc., while No. 5 tweezers or those with a thinner tip are used for small parts or adjusting hairspring isochrony, concentric circle and various fine works.

Usage:Don't use too much force. When clamping parts, don't clamp them flat. It's better to find a proper place to clamp them vertically, so as to avoid scratching the polished surface of parts due to improper force.

be careful:If the tweezers are blunt or missing corners, be sure to sharpen them with a grindstone. Do not use thin tweezers to clamp thick parts, or use thick tweezers to clamp small parts. This will easily cause damage to parts or tweezers.

15. Needle opener

Application: For the purpose of removing the pointer, in order to meet the needs of different types of watches, there are not only general needle openers but also hollow out watches and flat needle extractors without pointer sleeves.

Usage: When using, all hands on the faceplate must be fixed in the same direction first, and then the hands shall be pulled out vertically with the applicable needle opener.

be careful: Before pulling out the needle, it's better to use a special opening needle pad between the pointer and the faceplate, so as not to crush the faceplate.

16. Needle press

Application: The tools used to replace the disassembled pointer are of different sizes, the large one is used for the hour hand, and the small one is used for the minute hand (the second hand is pressed in with a sharp willow branch).

Usage: Align the hole of the needle presser with the clockwise or minute needle sleeve and press it in vertically.

be careful: This is the most commonly used specification. If the pointer is of special specification, a special needle press must be used. There is a complete set of needle pressing devices on the market, which is suitable for all kinds of needle pressing.

17. Machine oil

From left to right, 8200 clock oil (heavy oil) is used for large gears, 8300 spring oil, 9010 / 2 high-grade oil, time wheel and escapement system, 8000 general oil, and general gear.

Application:Parts running too long will produce wear, must point on the appropriate oil to increase lubrication, reduce friction.8200 is clock oil (heavy oil), which is used on larger gears;8300 is winding oil, which is used for winding;9010 / 2 is mechanical gear oil (Advanced gauge oil), which is used for mechanical timing gear train and escapement system;8000 is general surface oil, used for general gear or quartz surface gear train.

Usage:Dip a proper amount of oil on each part with oil pen.

be careful:Each kind of oil has different uses. It must be used in accordance with the regulations in order to give full play to the protection of the watch. Don't use it to the end for the convenience of the moment. It's the invisible killer of the watch.

18. Oil pen

Application: A group of 4, with different thicknesses, can be distinguished by color.

Usage: Black for 8200, for the top drive system; Blue is suitable for 9010 / 2, used for gems; Red is suitable for quartz oil and quartz gear;Yellow is suitable for 8300, which is used for winding.

be careful: Each kind of oil has a special oil pen, which can't be mixed with other oil, otherwise, the oil is easy to deteriorate.

19. Automatic oil pen

Application: It is used to light oil on parts. There is a screw to adjust the oil quantity, which can control the oil quantity.

Usage: Put the oil to be used into the pen, lift up the oil pushing rod, and drop the oil after putting it down. It is quite convenient to use and suitable for light oil, that is, water-based oil.

be careful: As the tip of the pen is very thin, it must be pressed and put gently when using.

20. Oil box

Application: It is mainly used to install different parts of oil. There are different specifications in a single box or a group of 4 boxes. As long as different oil is loaded, it is convenient to use at any time. The middle slot is to remove the residual oil stains on the used oil pen, so as to ensure that it will not be mixed with other different kinds of oil in the next use.

If you are looking for a professional screwdriver manufacturerto customize your precision screwdriver set, feel free to contact us today! We provide high-quality, customizable toolsfor various repair needs.

BECOME A WHOLESALE PARTNER

Get 10% off on orders over 500 units. We offer exclusive B2B pricing, OEM packaging, mixed batch support, and fast global delivery. Partner with a trusted screwdriver manufacturer to boost your margins.